Introduction of item

Jinwoong Airsys loves nature that breathes with people.

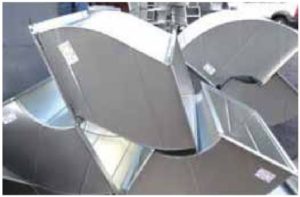

Square duct

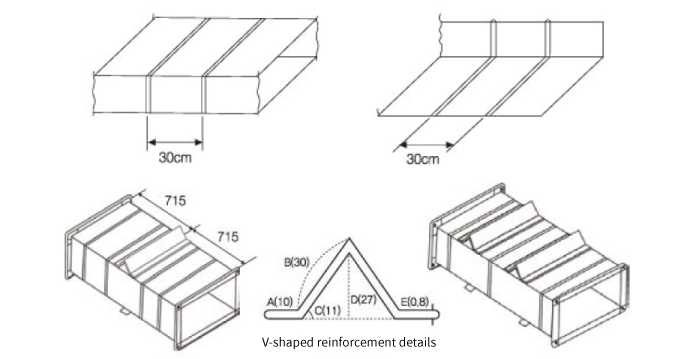

Every process of straight pipe duct from cutting, seam T.D.F flange production, bending and assembly using zinc coated coil by CAD/CAM SYSTEM is fully automated and manufactured. The type of longitudinal joint can be manufactured by the PITTSBURGH SEAM method, and sealant is injected to prevent AR LEAKAGE.

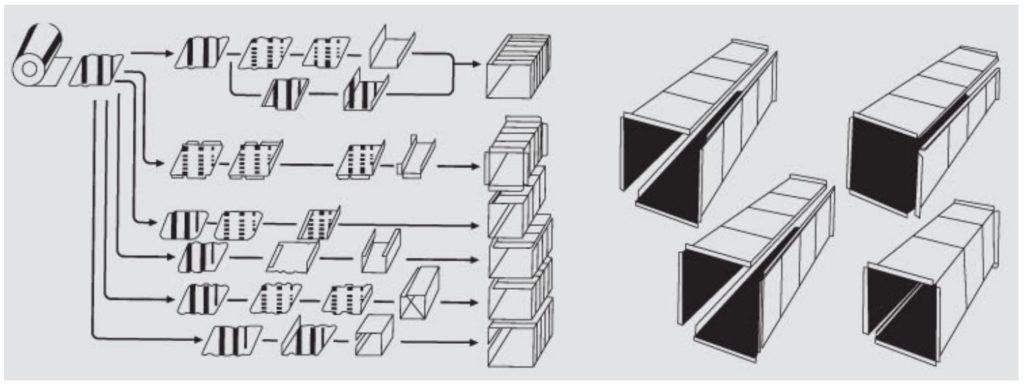

Square duct manufacturing process

- Manufacturing Process

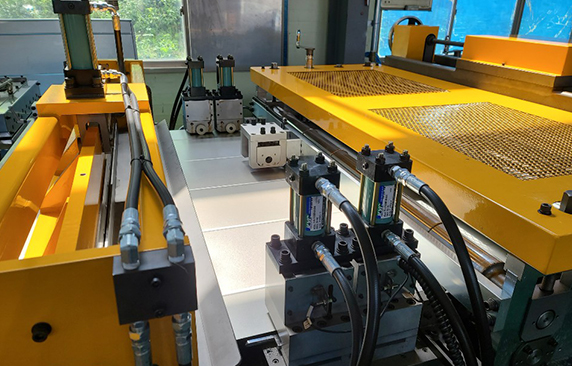

MICRO CNC CONTROL

It has an LCD monitor that shows the function and performance of each part, and the SEAM, JOINT, length, and standard of the straight pipe duct. Enter the quantity, etc.

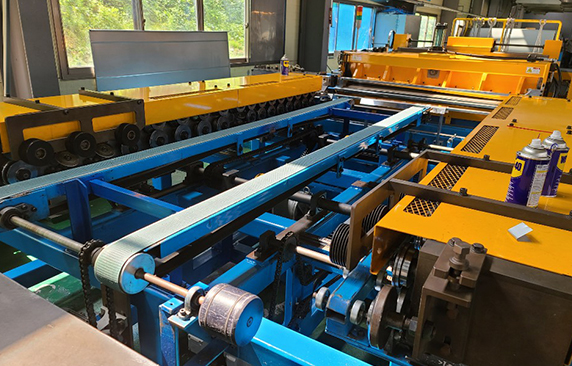

UNCOILERS & AUTOSELECT

As a part that prepares the material of the duct to be manufactured in the form of a coil, the coil of 5 gauges can be prepared, and it is automatically fed by Autoselect.

STRAIGHTENING & BEADING & NOTCH

The coil plate work, reinforcement work, and ear picking work are performed by Computer Contpol.

FOLDING & SHEARING

It is molded into Pittsburgh seam male and femal fo with a fold-down type, and'reputation', '4piece','L','U. Cut it in the form of'Wrap Around'.

SEALANT

Inject sealant into the duct seam.

T.D.F ROLLER

TDF Hurenji (process the spearfish)

BREAK SYSTEM

Bending in the form of'','c',

'Wrap' as specified by the CNC Controller.

CORNER MACHINE

Corner plates are automatically connected to the square of the finished duct.

PITTSBURGH SEAM CLOSER

Automatic joining of the Pittsburgh Seam.

Square curved duct

After data is input by the Cad/Cam System, the cutting process is automatically cut by a plasma cutting machine, and the provided setting is seam production, TDF flange production, bending and assembly by a forming machine. Produced by the process.

Manufacturing process

COMPUTER DRAWING

PV 2000 COMPUTER DRAWINGOZ Precision design

PLASMA

Plasma cutting according to the entered program

BEADING

Beading U-shaped reinforcement groove

PITTSBURGH SEAM

Curved pipe pittsburgh seam work, curved part seam work

T.D.F FLANGE

Assembling after TDF flange work

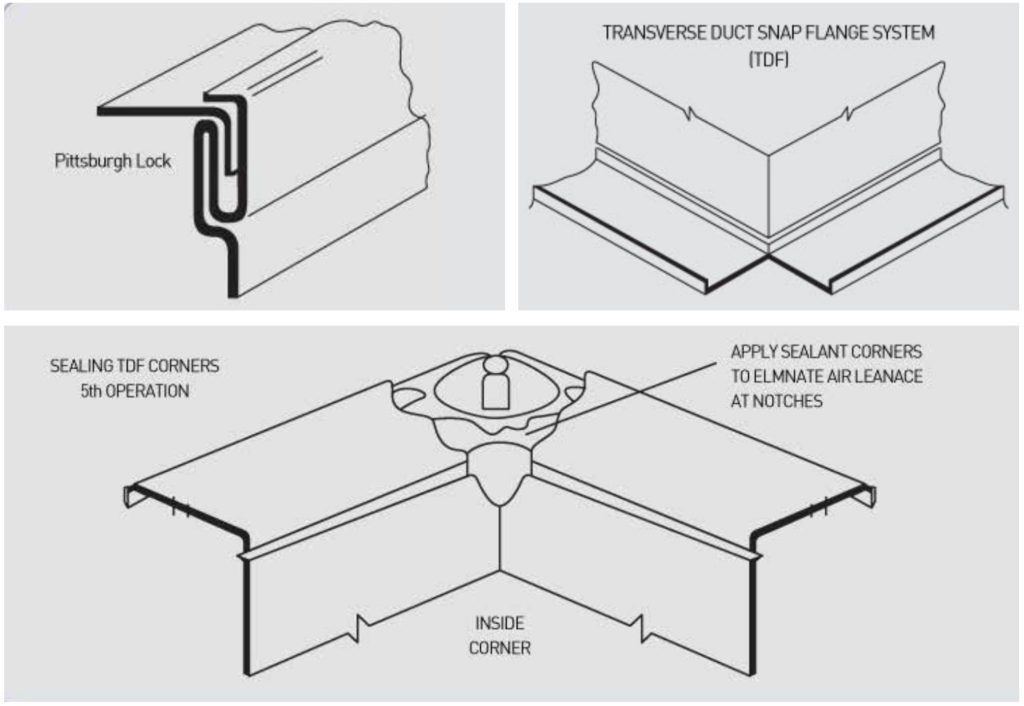

T.D.F DUCT SYSTEM

What is the cost-saving automation synduct method?

It can be seen as a great innovation of T.D.F (Treansverse duct flange duct flange 02 491).

In other words, it is a method of directly molding the flange to the duct body by changing the inefficient method of manufacturing the angle flange or flange bar, which is mainly used in the existing manufacturing. Connect the duct using 4 bolts, nuts and 8 TDF conrner plates and complete the assembly with T.D.F Cleat. Manufacturing is simple and fast, and production efficiency and production volume per unit time are increased. By not using angle flange or flange bar, manpower is saved, installation is easy, and air leakage can be minimized.

Conventional duct manufacturing uses 3’x6′, 4 x8′ galvanized steel sheets (GI Sheet), which caused a lot of material loss regardless of how it was cut. It leads to stubs, and air leakage is easy to occur at the joints, but the TDF Duct uses 5’galvanized coil, so it is convenient to manufacture, less material loss, and can produce accurate and precise ducts regardless of the size of the duct. I can.

Precision of T.D.F Duct

Conventional DUCT manufacturing caused a lot of material loss by using 3’x6′ and 4’x8 galvanized steel sheets (GI.SHEET). Due to the limitation of the size of the material, the application of SHEET always leads to many pieces of ducts, resulting in poor airtightness at the joint. TDF DUCT is manufactured by COMPUTER CONTROL using 5’galvanized coil, so it is possible to produce precise DUCT with high accuracy and airtightness without being limited by the size of the duct and with little material loss.

Conventional DUCT manufacturing caused a lot of material loss by using 3’x6′ and 4’x8 galvanized steel plates (GI.SHEET). Due to the limitation of the size of the material, the application of SHEET always leads to many pieces of duct, resulting in poor airtightness at the joint. Since TDF DUCT is manufactured by COMPUTER CONTROL using 5’galvanized coil, it is possible to produce precise DUCT with high accuracy and airtightness, without material loss and not limited by dimensions of DUCT.

T.D.F connection part

The thickness and connection of tin depending on the size can be divided from 1-pice type to 4-pice.

DUCT SEAM

Pittsburgh Lock Seam is used for the straight pipe duct corner joint method, but the inner corners are sealed after manufacturing to prevent air leakage when the joint is manufactured.

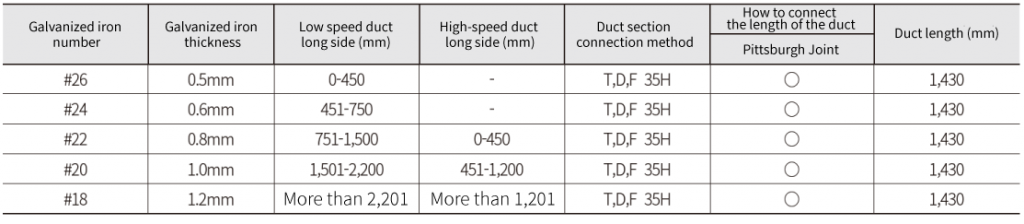

T.D.F DUCT clip spacing and quantity

1. CLIP The maximum distance between CLIPs is 275mm-228mm, and it is usually 75mm~150mm.

2. The standard length of the clip is 150mm, and the number of clips is as shown in the picture above according to the size of the DUCT.

3. When DUCT SIZE is less than 450mm, use 1 CLIP.

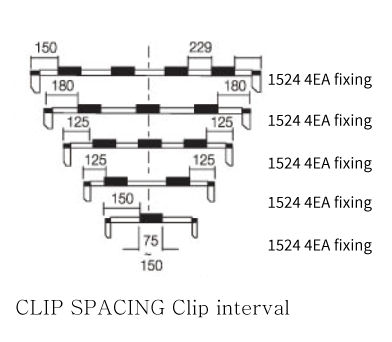

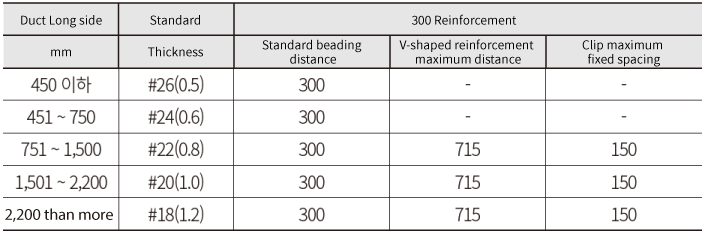

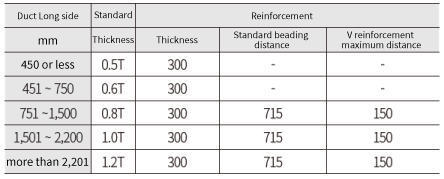

DUCT reinforcement

The reinforcement of DUCT plays a role in reducing vibration and noise and increasing the bearing capacity when high voltage is applied in the duct.

1. Reinforced with U-shaped beading on the body of DUCT at 30cm intervals

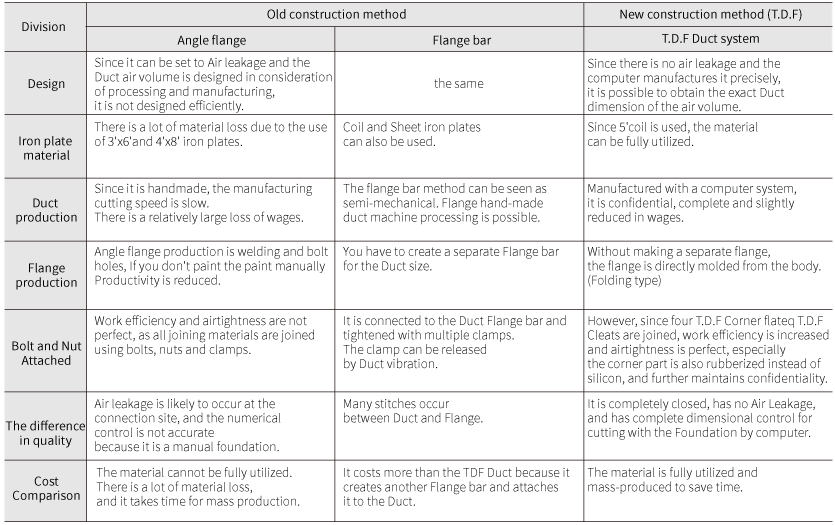

Comparison between T.D.F method and conventional method

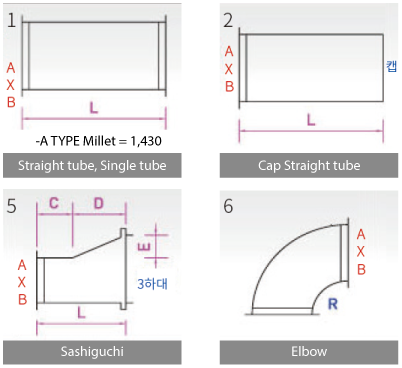

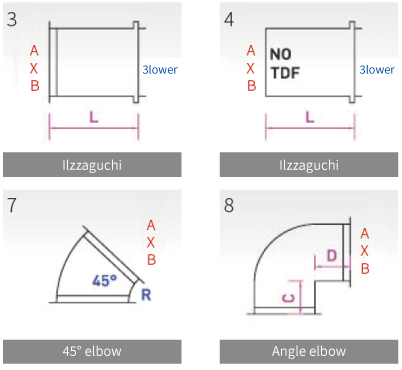

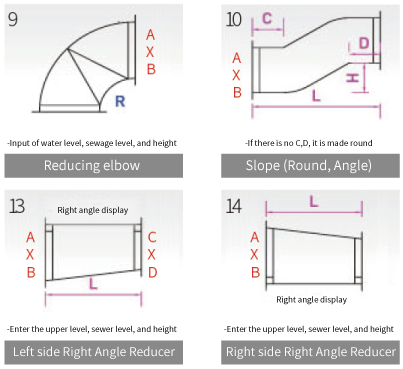

Square DUCT production model

Table of reinforcement dimensions

Remarks

- Including CCUP, TDF Corner

- Including straight pipe ratio 7: 3 standard premium (GI 25%, SUS 28%)

(Extra change when the curved pipe ratio is high)</ li> - All PITCHBURGH method applied

- Transport cost, VAT not included,

- SPIN, TURNING VANE HOPPER, CHAMBER separate unit price applied

- Separate inquiry (unit price list)